Category: Uncategorized

Cheesemaking: How To Make Derby Cheese With Sage

This cheese is a Derbyshire cheese that was created during the early 20th century. It is a moister, softer and earlier ripening version of Cheddar. Sage is added to this recipe to give it a delicious twist.

Recipe

What To Do

2 Gallons of Milk (Not UltraPasteurized)

2/3-3/4 Packet C101 Mesophilic Culture or 3/16 tsp MA11 Culture*

1/2 Tsp (2.5 ml) Single Strength Liquid Rennet

0.8 oz Salt

6-12 Sage Leaves for Aroma/Flavor

6-12 Spinach Leaves for Color

Calcium Chloride (for pasteurized milk)

What To Do

1. The first step is to heat and acidify the milk. So let’s begin by heating the milk to 84F. To do this, place the milk in a container and then place it in a large pot of very warm water. If you heat it on the stove, be sure to heat it slowly and stir it as it heats if you heat it on the stove.

Once you are done heating the milk, you can add the culture. The powder can become very cakey and sink in clumps so to prevent this, sprinkle the culture over the surface of the milk and then let it sit for a couple of minutes. This allows the powder to re-hydrate before you stir it in. After stirring, let the milk sit for a further hour so that the culture can get to work.

2. While you are waiting for the milk to warm and ripen, you should begin preparing the sage.

– Clean the leaves well in cold water and let them soak for 10-20 minutes. This can help remove some of the herbal bitterness.

– Make sure you drain the leaves well and then add around 2-4oz. of cold water and blend the herbs into a fine puree.

– Now set the puree aside for later use. The puree should be dark green once the foam subsides.

3. After an hour of ripening, add in the single strength liquid rennet. Stir the rennet in for about a minute in a slow up and down motion. The rennet will begin to coagulate the curd, let it sit for another hour. You will see the milk thicken after around 20 minutes, but it still needs the full hour for a proper curd to form.

One way to check for a good card, insert a knife into the curd at a 45-degree angle and lift slowly until the curd breaks. The edges should break cleanly and the whey that will rise should be clear, not cloudy.

Remember to utilize coagulation times by sanitizing the cheese molds and draining boards.

Once the curd is firm, you can begin to cut it into 1/2-5/8 inch pieces as evenly as possible, using a knife to make vertical cuts.

Stir the curds gently enough to keep them separated for about 5 minutes. This will allow for the curd surface to harden enough for a long stir. Make sure you allow the curds to settle for about another 5 minutes to allow the whey to rise.

Begin to stir the curds consistently for the next 15 minutes and bring the temperature back up to 84F if it has dropped.

The curds will appear to be soft and show very little structure, while the whey may be opaque.

4. You can now begin to dry out the curds. This can be done by increasing the heat slowly to 92F. You need to increase the temperature at the rate of 3-5F per 5 minutes at the beginning, making the total cooking time 15 minutes, but may be extended if the curds are still soft.

The curds will become firmer and the whey will appear more translucent.

You should examine the curds to make sure enough moisture has been removed. Broken curds should be firm throughout and the curds should be firm throughout and the curds should have a moderate resistance when pressed between the fingers.

The curd is ready when a handful of curds pressed together easily separate with a little pressure from the thumb. At this point, the curds can be allowed to settle under the whey.

5. The whey should first be removed to the curd surface in the vat. You can transfer the curds to a colander lined with butter muslin. Allow them to be drained for a few minutes, gently stirring the curds will make sure the whey drains off.

6. Once you have released all the free whey, fold the drainage cloth over and turn the cheese mass to allow it to consolidate. Then place another identical tub with no holes on top and add 1/2-3/4 gallons of water. This is to keep the curd warm and to help with consolidating the curd mass.

At this point, the final acidity has developed and some calcium will be leached from the curd and flow off into the whey. The structure of the curd will also begin to change.

Unwrap the cheese mass and turn it over and rewrap every 15-30 minutes for the next 1-2 hours while final acid is produced. The final acid being pH=5.3-5.4 TA%=.45-.55 and more whey is expelled. The longer you let the curd develop, the more it is turned and the drier it will become.

Once the curd has ripened, you should see a change in its structure. It will be well consolidated and flatter. When you break it, you should see an elongated individual curd profile.

7. Now the curd should be torn or cut into small walnut sized pieces. This will allow for the salt to penetrate to the center of each curd and stops the development of excess acid which is already near its targeted development. Failing to do this will result in an over acid cheese.

8. This next step is about adding the salt and sage to the curd. About 2% of the curd weight in salt should be added. The final curd weight of 2.5lbs will need around .8oz of salt. Add the salt in 2-3 cycles, with time between for the salt to dissolve.

Once the salt is absorbed, you can add the sage/spinach infusion to the broken curds. This should now have dropped to room temp and will be cooler than the curds. This will cause more of the sage liquid infusion to be absorbed into the curds. It is essential to add the salt before the sage infusion because the whey released from salt additions will cause some of the sage flavor to be released as well.

Stir the sage infusion well into the curds and allow them to rest for a few minutes while you prepare the mold.

9. Make sure the mold and cloth have been sanitized. The curd can be pressed into the mold and compacted with a firm hand to begin the consolidation.

Fold the cloth over the surface and the follower placed on top so that the press weight is on the cheese surface and not in the mold itself.

10. This is the stage where you begin pressing the cheese. To press the cheese, begin very light and then slowly increase the press weight to a moderate level:

– 30 minutes at 15 lbs

– 60 minutes at 20 lbs

– 2 hours at 35 lbs

– Overnight at 40-50lbs

After the initial drainage of whey, the rate of whey running off will be a matter of drops and not a stream of whey being released. This is a good rate of whey removal during pressing and will slow down even more as the residual free moisture is released. You should see tears of whey weeping from the form very slowly. When it stops completely, increase the weight slightly.

Remove the cheese from the press and unwrap, turn and rewrap and put it back into the press at the above intervals to assure an even consolidation.

11. Now it is time to age the cheese. You can place it into the aging room at 52-56F and 80-85% moisture. Age the cheese for around 4-6 weeks, after this time, the cheese will be ready for serving. Or you can leave for a further 3-6 month for a complex aged texture and flavor.

A How-To On Pairing Cured Meats and Cheeses

Pairing Cured Meat And Cheeses

When pairing things, two approaches generally come into play. The first approach would be to pair like flavors, for instance, two sour ingredients. With this, the similar flavors may cancel each other out and let the other flavors flourish. The second, more common approach is that opposites attract, this takes play in every type of pairing there is, not just in food.

Sometimes, cheese alone on a cheese plate is not enough. You may want to consider other easy additions to compliment the cheese such as: honey, fruit, and crackers. However, if

you’re looking to really add something different and like no other, cured meat is the way to go! It might sound like a difficult pairing, but it really isn’t hard at all. The main tip is to make the most out of it, this can be done by knowing some of the general principles.

The best way to pair cured meat and cheese is through opposites. Unlike wine, beer, or spirits, meat is full of fat, protein, and salt, just like cheese. So you need to proceed with care when pairing the two as you can end up having an overwhelming flavor.

The two major groups that cured meat falls into are: encased or whole muscle. Encased meats have a noticeable tang to them, with intense aromas of black pepper, red pepper, fennel, truffle, and so on. Whole muscle meats are much sweeter, nuttier and more “meaty” like. It’s important to keep this difference in mind when thinking about a meat’s acidity and sweetness.

Source: https://s-media-cache-ak0.pinimg.com/736x/00/2b/d6/002bd6c7db95fe3f385b674bbc1c5934.jpg

Source: https://s-media-cache-ak0.pinimg.com/736x/00/2b/d6/002bd6c7db95fe3f385b674bbc1c5934.jpg

Pairing With Whole Muscle Meats

When pairing wine with cheese, if you’re in doubt, it’s best to pair wine and food made in the same region. This is the same for meat and cheese, it also brings us to the notion that it is good to start with a classic:

Parmigiano Reggiano and Prosciutto Di Parma literally begin their perfect pairing at the source. It is commonly known that the whey by-product of Parm is fed to the hogs, whose back legs actually become Prosciutto Di Parma! So one ingredient quite literally fuels the other, thus becoming the perfect pairing.

Prosciutto Di Parma, like all whole muscle cured meats, should be sliced into very thin sheets, neatly trimmed with a ribbon of fat. It melts away on the tongue into a delicious whiff of hazelnut and sweet butter. Parmigiano Reggiano on the other hand is quite the opposite of the elegant Prosciutto Di Parma. It is coarse and craggy, with a distinct tang in the mouth. It shares toasted and nutty flavors but has a leanness because of its partially skimmed milk.

Important lessons to learn from this pairing:

- Flavors which compliment, focus on what is shared, if you can rely on other elements for the contrast needed.

- The texture is important. A mushy, floppy or semisoft cheese paired with a thin slice of meats lacks the contrast needed for a good pairing.

- Acidity is important. In this pairing, it is the cheese, in other pairings it could be the meat. But one element must contribute the sensation of tart, citrusy, mouthwatering brightness to cut out the protein and fat of the other.

Another classic pairing which works on these principles:

A lightly smoked whole muscle meat called Speck is brilliantly matched with a cheese which is textually like Parm, but tastes completely different: Piave. Astringency in the meat is completely reliant on the wood that the meat is smoked over, while the cheese bursts with pineapple and tropical fruit. That is where it is opposite to our first classical pairing: the cheese handles the sweetness while the meat takes the savory lead.

Pairing With Encased Meats

The perfect instruments for spreading an even dipping in the right cheeses come from small-diameter sausage links, which are cured slowly over time and sliced into quarter-inch- thick coins. Most sausages give off amazing spices, garlic, smoke, or even heat, which adds a third component of flavor to play around with when pairing. A well-liked favorite:

Paprika- and cayenne- laden Spanish- Style Chorizo immersed into a perfectly ripened sheep’s milk La Serena will make your mouth water. La Serena, which is a bit airier than custard and full of tart, vegetal and what some would say sour flavors, is a thistle-coagulated cheese. This cheese succeeds in cooling the heat of the chorizo and you’re left with the sweet taste of paprika and garlic. Other cheeses which also work well are Fresh Ricotta or Goat’s Cheese. Cheeses that preserve lactic notes of fresh milk, but earthly notes of age also work well as cooling cheeses to spicy, smoky, or gamey meats.

Minding your meat’s acidity and added flavors is generally what to keep in mind when pairing cheeses with cured meats.

Cured Meats Which Are Cheese-Friendly

Not many of Europe’s cured meats make it into the U.S. but there are still a lot of domestic producers creating great cured meats with European traditions. Here are some brands to try:

– S. Wallace Edwards and Sons

– Olli Salumeria

– La Quercia

– Olympic Provisions

– Creminelli Fine Meats

What is the Perfect Cheese For Pizza?

September 5th marked a day of celebration for America, and perhaps, even much of the world… because who doesn’t like pizza and cheese or both? Unknown to many is that September 5th is National Cheese Pizza Day. You know with the birth of smartphones and mobile apps came the phrase “…there’s an app for that”, well in similar light, if you love a food or, in this case, a combination of foods, a new axiom may take shape here, “…there might just be ‘National’ day for that”. A day that puts the focus of pizza and cheese, two delicious foods in and of themselves, but when together, spark a whole new revelation of culinary marvel… who would not love a day just to celebrate such a marvel? The answer should be simple… no one.

There has been an age-old question that continues to make the mind wonder and wander, that is… “Is there a perfect cheese to put on pizza?” Dr. Bryony James, a scientist whose research centers on food microstructure and food material science in New Zealand at the University of Auckland dove right in to find an answer the this question. Dr. James’ team of scientists study the building blocks of food and even experiment with structural composition of various foods that can influence its functionality. Ideally, their line of scientific research would allow them to develop a potential hypothesis for such an experiment. As the team began initial studies of the “best cheese for pizza”, they already knew that, historically, Mozzarella was highly favored and the most commonly used cheese for pizza topping.

Among countless scientific trials and experiments, the team researched cheese based on browning and blistering. These variable were designated as focuses of research as they were found to be the most looked upon features by consumers. Examining the properties, features and characteristics of cheese could potentially lead to further discoveries of the ideal cheese or in some cases, the ideal combination of cheeses to use on pizza. Other cheeses the group extended their research to was Cheddar, Colby, Emmental, Gruyere and Provolone. The actual experimentation itself was conducted by state-of-the-art technology, as opposed to human hands. As human judgment would have been idea over the work of a machine, it would have been far more time-consuming and brought the idea of a “bias” trial or opinions when bringing human emotion and interaction into the picture.

Of the properties of cheese that were measured for this experiment, smell, texture, melting properties and color were at the forefront. Researched revealed that some cheeses like Cheddar did not produce a favorable level of blistering while the likes of Gruyere did not properly brown after melting, which can be attributed to the oil content within the cheese. The results clearly indicated that although Mozzarella might be the traditional favorite cheese topper for pizzas, there might not be that “perfect” cheese or combination of cheeses, as each cheese’s characteristics and properties, when undergoing melting, might be desirable for one consumer, but desirable for another.

Source: http://www.cheeserank.com/post/the-science-of-pizza-cheese

Is Raw Cheese Healthy or Unhealthy?

We’ve all eaten cheese at some point in our life, unless health reasons prohibit us from doing so. But what is “raw” cheese? No, it is not cheese that is not cooked thoroughly. Instead, raw cheese is made from milk that is not pasteurized. For a while now, food critics and health experts alike have continually debated the benefits and disadvantages that consuming raw cheese can have on one’s health.

Consuming unpasteurized cheese is considered the thing to do today, as buying artisanal foods as such is trending very high in today’s market. There are some who believe consuming cheese’s raw version is a healthier option than its counterpart, pasteurized cheese. However, as some would believe that raw cheese promotes health, there are others that contradict such claims.

THE BENEFITS

As program director at Oldway’s Coalition, Carlos Yescas, noted, there are a number of benefits to eating raw cheese. Among the key benefits are the diversity of microorganisms that are contained within the raw cheese. While uncertainties still remain due in large part to the human biological response to these microorganisms, the majority of the microbes present in raw cheese have the ability to combat disease and bodily infections. While many folks have shown concern with raw cheese and its production, Yescas assures that at the forefront of safety measures for producing raw cheese, is the diligence in making certain that good milk is sourced. It is the cheese-makers utmost priority to ensure that quality of the milk is superior which includes animal living conditions, animal nutrition and diets and animal husbandry. Because of the great risk involved when not pasteurizing the milk, a great deal of time, energy and resources are invested in making certain the conditions surrounding the milking-process is pristine.

Raw milk also has similar nutrients that are normally contained in pasteurized cheese, such as protein and calcium, among others while tasting identical to their counterparts.

THE DISADVANTAGES

Normally, you’ll find the cheese-making process to use milk that has been pasteurized. The pasteurization process involves heating the milk to destroy and pathogenic microorganisms that might be harmful, while maintaining its integrity of nutritional quality. In some cases, the pathogenic microorganisms can make you fall ill, especially those with lower immune systems like children, pregnant and breastfeeding women, older folks and those with chronic diseases. It is best advised to not consume raw cheese if under these conditions.

THE FINAL SAY

A number of raw cheeses can be found at local markets, by local producers. It is of the utmost importance to check and ensure that the conditions and environment of where the cheese is kept up to health and safety regulations. If you decide to consume raw cheese, make certain you are aware of where you are buying it from and how the methods in which the producer treats and raises the cows for milking.

A Cheese So Expensive, It Makes Gruyere Seem Affordable

When it comes to cheese, most really never think twice about the differences in cheese, texture, taste, sharpness and other characteristics that make cheese, well… cheese. As long as there is cheese available and on your burger, shredded on your pasta, topped on your salad or wrapped in your taco, that is the main focus on the minds of most when thinking “cheese”. What most do not realize is that, aside from your general cheese, such as Swiss, American, Cheddar among others, as the list goes on seemingly indefinitely, there is an unrealized and undiscovered “world” of cheese. From the United States to Canada to all of Europe, there are cheeses that are made every day that most are completely unfamiliar with.

Entering this undiscovered world of cheese, we travel all the way to Serbia, the location of one of the most expensive cheeses on Earth. What makes it so expensive is that it can only be made in Serbia as the milk used to make this cheese does not come from cows, nor does it come from goats, but instead, to make this cheese, the milk comes from the rare Balkan Donkey. The name of this cheese is “Pule” (poo-lay) and commands the hefty price in the world. In 2012, Pule was sold in bulk at a price that was considered discounted at over $750 per pound. The price for Pule increases exponentially on the open market going for upwards of $1300 per pound.

Why a cheese costing a seemingly ridiculous amount of money? Well, the process of making Pule itself is where much of its price is argued. Contrary to the modern marvels that would allow machines to extract milk from cows and goats, the milk coming from Balkan Donkeys is extracted by hand, each day, three times per day. To make matters even more intricate and arguable for the price paid for this cheese is that when milking these donkeys, very little milk is given off per sitting of milking these donkeys. All told it takes over 15 donkeys to produce a gallon of milk each day, and it takes over 3 gallons of milk to produce 1 pound of Pule.

Pule has been very popular for a very long time, especially to those familiar with its existence. Rumor had it that tennis star, Novak Djokovic used all of his winnings from his tournament to purchase the entire county’s supply of Pule, only later to discover the rumor was just that, a rumor. The global supply of Pule, albeit, a small supply relatively speaking, comes from a herd of Balkan Donkeys housed in a special nature preserve in the city of Zasavica in Serbia. Workers at the preserve view the production of Pule as a means of promoting the Balkan Donkeys which are considered by all right, an endangered species.

Cheese is Everywhere in Wisconsin… Even on the roads?!

We all know that Wisconsin is known for its cheese-making prowess and it has become well-deserved honor through the course of history. Cheese and cheese-making have become such a mainstay across Wisconsin that vehicle license plates carry the slogan “America’s Dairyland” while lawmakers have officially coined the bacterium found in Monterey Jack cheese as the official microbe of the state of Wisconsin. A little over the top? Perhaps, but to each their own. However, one thing that takes Wisconsin’s love for its cheese from interesting to just… mind-blowing… is the use of cheese as melting agent for its city streets during winter.

In 2013, Milwaukee commenced a program that would use cheese brine to prevent citywide roads from freezing over during winter. The melting solvent was a mixture of cheese brine and traditional rock salt. The purpose behind this program was to execute a more cost efficient means of treating roads during the year’s harshest weather.

Photo Credit: Tom Lynn/New York Times

According to Jeffrey A. Tews, operations manager for the city’s public works department, “You want to use Provolone or Mozzarella, which has the best salt content. You have to do practically nothing to it.” Tews and his crew, in the program’s infancy, spread the solvent across the streets of Bay View, a neighborhood on Milwaukee’s north side.

A group of experts noted that efforts to reuse the brine from cheese was only a matter of time before that came to fruition, especially considering a state so enamored in cheese like Wisconsin.

A local city official in Milwaukee noted that the state is trying to extract every possible use out of cheese it possibly can. He went on further to note that if the program continues to make leaps and bounds, it will most likely be implemented by cities all across the country. While the prospect of this program does sound like a genius idea, it does come with the potential for negative impacts, as does any newly piloted program in its infancy. Some of the issues that may surface range from:

- Would the brine put out a cheese odor that would become bothersome for residents?

- Would the scent attract rodents or other animals?

- Would the pros of using cheese brine in the mixture of this solvent be enough to justify the transport and storage requirements for the brine, over the long haul?

If at first this sounds like a laughable program, think about the facts in play. Wisconsin produced well over 2 billion pounds of cheese in 2012. With such lofty amounts of cheese production comes an overwhelming supply of brine, which would otherwise be sent to the waste plant. Cheese brine, by city requirements, is allowable as a treatment on roads if limited to an 8 gallon to one ton rock salt ratio. The benefit of using brine in solvents for treating roads works for both parties, the dairy plants and the city’s public works departments. The dairy plants save on hauling costs for those municipalities in need of brine for road treatments who are willing to travel to the plant and haul it away for them (saving an average of $20,000/year) while the municipalities save on the cost of rock salt with the addition of brine to their treatment solvent (saving an average of $40,000/year). In the long run, it would seem that while there are both pros and cons on the table, I would suspect that the benefits of using brine to treat winter roads would tremendously outweigh the shortcoming of its use. I could see this become a nationwide program over the next decade.

Our Beloved, Rita: A Life of love and a Legacy of Hard Work and Extraordinary Customer Service To Her Community

It all started 70 years ago in the town of Linz, Austria where our beloved, Rita Shisler opened her eyes to see the world in front of her for the very first time. Rita was born on August 12th, 1946 to her parents, Ludwig and Henrietta Baumgartner. Rita spent the earliest years of her life in a Displaced Persons camp in Ebelsberg, Austria. Her father Ludwig, worked for the American soldiers in Ebelsberg while her mother, Henrietta, went to nursing school. Having lived in Ebelsberg for 6 years, Rita had run into a major health scare as a child, developing Diptheria, a serious infection of the nose and throat. The infection had become grave to a point where doctors questioned her survival because of it. Rita went on to say, “During the Diptheria outbreak, there was a large room where children with the infection would stay, eat, sleep and receive their medications. During the night, several kids were shipped out because they had gone to heaven.” Later on, Rita was sent to another camp for food and medications in an effort to battle this infection. Miraculously, Rita pulled through and conquered the odds.

It all started 70 years ago in the town of Linz, Austria where our beloved, Rita Shisler opened her eyes to see the world in front of her for the very first time. Rita was born on August 12th, 1946 to her parents, Ludwig and Henrietta Baumgartner. Rita spent the earliest years of her life in a Displaced Persons camp in Ebelsberg, Austria. Her father Ludwig, worked for the American soldiers in Ebelsberg while her mother, Henrietta, went to nursing school. Having lived in Ebelsberg for 6 years, Rita had run into a major health scare as a child, developing Diptheria, a serious infection of the nose and throat. The infection had become grave to a point where doctors questioned her survival because of it. Rita went on to say, “During the Diptheria outbreak, there was a large room where children with the infection would stay, eat, sleep and receive their medications. During the night, several kids were shipped out because they had gone to heaven.” Later on, Rita was sent to another camp for food and medications in an effort to battle this infection. Miraculously, Rita pulled through and conquered the odds.

In 1952, Rita and her parents moved to Germany when her sister, Minnie, was born. Following their stay in Germany, her father thoroughly enjoyed the work he did for the American soldiers back in Ebelsberg that he wanted to bring his family to America. In an effort to come to America, they applied through the Catholic Church and eventually found a sponsor in New York. Growing up, Rita’s time was dedicated to school while taking care of the children, the cooking and the cleaning at home, while somehow managing to carry on her duties at work at Akron City Hospital. Rita belonged to the German Club after coming over from Germany, where she participated in youth group events such as singing and dancing.

A time later, as a senior high school girl, Rita tested out of the Akron City Rubber Company. The Akron City Rubber Company was testing senior high school girls in office practice for shorthand and typing. From there, Rita was placed with the BF Goodrich program, but instead decided to move to Defiance, Ohio, where she continued her collegiate education as she had wanted to go to law school. As part of her collegiate resume, Rita continued classwork at The University of Akron and Kent State University in the years following. She also worked for the Holiday Inn where she was sent to the Culinary Arts program at Cornell University. Soon, thereafter, Rita met Dan Shisler, and it was a match made in heaven and the beginning of the marriage of Rita and cheese.

THE BIRTH OF A CHEESE HOUSE

Shisler’s Cheese House was originally owned by a gentleman named Fred Biery and was then called Biery Cheese. Dan’s father, “Grandpa Shisler” bought the cheese store from Fred Biery when he retired from the railroad, after Biery traveled with his wife to Switzerland to convince Grandpa Shisler to do so. Eventually, Dan bought the cheese store from his father, and Shisler’s Cheese House stands today at the corner of Kidron Rd and US-30.

As the cheese store was in its infancy stages, Rita didn’t quite have that firework passion for cheese that she has today, and rightly so with anyone that is initially put into foreign waters. But, overtime, Rita developed a passion for business, customer service and of course, a burning passion for cheese as Shisler’s Cheese House has become her livelihood. The work, the customers and the cheese keeps her coming back for more. As Rita said “I am too old to start a new career” and why should she tamper with something that isn’t broken. Never mess with a good thing, or in this case, a great thing! More importantly than the cheese she sells to her customers, are her customers themselves. She treats them like royalty, because they are royalty. She has built rapports and lifelong friendships with countless customers over the years and they continue to come back knowing that they will have a personalized touch to their purchase, and more importantly, their visit with Rita. “I feel like I have an audience when I’m out there”, as Rita always delivers for her customers, no matter the day or time. She always has room, in what seems like an unending schedule, to talk with her customers and make them apart of her family, something you cannot find these days.

Last Christmas, the store was overflowing with customers, as is the norm for that time of the year for the store. Rita noted that it was the greatest thing seeing three generations of Shislers working in the store that day… herself, her son Dennis and her granddaughter, Natalia.

Wishing you a wonderful, beautiful, Happy 70th Birthday, Rita! May the day, the smiles and the cheese be amazing on your birthday and every day that follows!

History Of The Monte Cristo Sandwich And Its Recipe

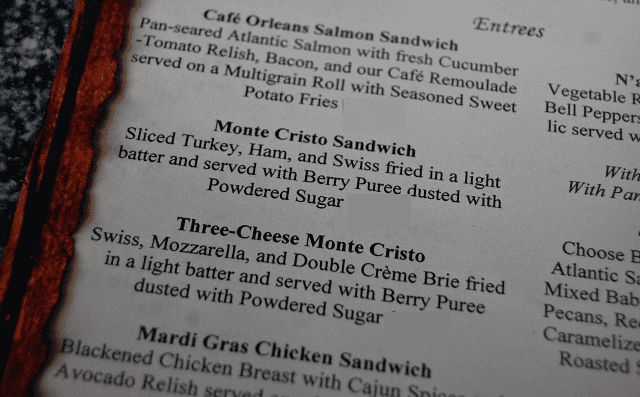

When thinking of the name “Monte Cristo”, what comes to mind? The Count of Monte Cristo? The Monte Cristo? The quest for the Holy Grail… wait a second, that’s Monte Python! On the tastier side of things, the most tantalizing of these is the Monte Cristo Sandwich. The Monte Cristo is a delicious sandwich served in delis and restaurants across the world. Known for its savory layers of Swiss cheese and ham, turkey or chicken. This deli delight is far and away a cheese lover’s dream sandwich.

What exactly is the Monte Cristo sandwich?

While the Monte Cristo sandwich tends to vary from restaurant to restaurant or from deli to deli, the general blueprint consists of two slices of white bread containing ham, turkey, or chicken, and slices of Swiss Cheese which are dipped in beaten egg and fried in butter. A classic Monte Cristo sandwich should come with a side of jelly in which you have the option to dip your sandwich for the best Monte Cristo Sandwich experience.

What is the origin of the Monte Cristo Sandwich?

1910s… Most culinary experts believed that the Monte Cristo Sandwich is a variation of a French dish called Croque Monsieur, a grilled cheese sandwich consisting of Gruyere cheese and lean ham layered between two slices of crust-less bread, fried in clarified butter and made in a special grilling iron with two metal plates. Croque Monsieur was served for the first time in a Parisian cafe.

1930s to 1960s… American cookbooks published in this time period showcased this sandwich under a myriad of names including… French Sandwich, Toasted Ham Sandwich and French Toasted Cheese Sandwich, all sounding delicious, but lacking a truly unique sandwich identity.

1950s… This sandwich was first served under the name “The Monte Cristo” in southern California in the 1950s

1966… Disneyland made its contributions to the ever-surging Monte Cristo Sandwich. It appeared on their menu at the Blue Bayou and Tahitian Terrace restaurants in New Orleans’s Square in Disneyland.

Ever since, the Monte Cristo Sandwich has made leaps and bounds in culinary notoriety becoming one of the most delicious sandwiches of our time and finding its place on menus of restaurants, delis, and other sandwich shops, nationally and internationally.

How to make the Monte Cristo…

Ingredients

- 12 slices firm-textured white bread

- Mayonnaise

- 12 slices Swiss cheese, each about 1/8″ thick

- 6 slices cooked ham, each 1/8 to 1/4″ thick

- 6 slices cooked turkey, each 1/8 to 1/4″ thick

- 3 eggs

- 1/4 cup half-and-half, light cream or milk

- Dash of salt

- 3 to 5 tablespoons butter or margarine

- Powdered sugar

- Parsley sprigs

- Red currant jelly

Directions

Thinly spread one side of each bread slice with mayonnaise. Then assemble 6 sandwiches, using 2 slices of cheese, one slice of ham, and one slice of turkey for each sandwich. Trim bread crusts and filling with sharp knife, making edges of sandwiches even; cut each sandwich in half diagonally.

In a shallow dish, beat eggs, half-and-half, and salt until blended. Places sandwiches in mixture and turn to coat; then let stand, turning occasionally, until all liquid is absorbed. Melt about 3 tablespoons of the butter in a wide frying pan over a medium heat. Add as many sandwiches as will fit without crowding; cook, turning once, until lightly browned on both sides. Remove from pan. Repeat with remaining sandwiches, adding more butter to pan as needed.

Place the sandwiches on an ungreased baking sheet and bake in a 400° oven until cheese is melted (3 to 5 minutes). Dust with powdered sugar and garnish with parsley sprigs. Serve hot, accompanied with jelly. Makes 6 sandwiches.

Why Heggy’s Chocolates are better than the Rest

Ask any passionate chocolate lover and he (or she) will tell you all about the deliciously rich, creamy and smooth Heggy’s chocolates. Heggy’s Candy Company has been offering premium high quality chocolates for over nine decades. Since the time of its establishment in 1923, the company has been providing consumers with premium hand crafted candies and chocolates throughout America.

Today, Heggy’s continues to be a family owned and operated business. They have been serving the community and customers with a high level of commitment and have continued to keep the almost extinct handcrafting quality chocolates and candies alive.

Withstanding the test of time, they have perfected the art of creating masterpieces in chocolate. Every single piece of candy and chocolate offered by Heggy’s is created with a lot of necessary patience and care. Candies and chocolates manufactured by Heggy’s are also packed to precision in individual wrappers. This helps retain their delicious flavor and freshness.

No wonder there are many devoted candy lovers in America loyal to Heggy’s. Chocolates and candies are offered today by this brand over the internet expanding its reach. You can choose from the delicious catalog and have the exquisite flavor of Heggy’s delivered right to your doorstep.

Heggy’s chocolates and candies are ideal as gifts for any occasion. Enjoy the unique taste of their milk chocolates or choose from the exciting range of mouth watering dark chocolates. Bite into the delicious milk chocolate crunch and savor the elusive taste of those buttery peanut brittle bits dipped in rich milk chocolate.

Reach out for the maple walnut creams or enjoy the amazing taste of milk chocolate sprinkled with English walnuts with a soft cream center. The popular milk peanut clusters chocolates come with a vanilla cream center covered with chocolate and fresh ground peanut blend.

If you love dark chocolate, choose the dark chocolate crunch, maple walnut creams, dark chocolate peanut clusters, dark chocolate brownie, peppermint and jersey creams, dark chocolate coated caramel or dark chocolate French mint. There is no dearth of choice.

Heggy’s also has on offer a range of rich caramels including the delicious butterscotch, mouthwatering almond and exciting Brazil nut, pecan, walnut and plain vanilla caramel. This is not all. Heggy’s offers a variety of high quality nuts such as the Redskin Peanuts, Spanish Peanuts, whole cashews, natural pistachios, fancy mixed nuts, roasted salted pecans, roasted salted macadamia nuts, smoked almonds and blanched almonds. If you love chocolates, candies and nuts, Heggy’s is an experience not to be missed.

Ohio Business Owner Receives Lion’s Club Leadership Award

District 13G of the Ohio Lions Clubs, at the District Convention, presented the first ever District Governor’s Association Award for Leadership and Dedication to Rita Shisler of the Orrville Lions Club. Rita is an immediate past president of the Orrville Lions, and was president for it’s Charter Year, in 2009 and 2010, helping to form the Orrville Lions. She has been appointed as Zone Chairman for Lions Zone 1, for 2011/2012. Lions International is the world’s largest service organization, with 1.35 million members in 206 countries.

Shisler, owner of Shisler’s Cheese House in Orrville, has been active as a board member of Wayne County Red Cross, Wayne County Convention and Visitor’s Bureau, Women’s Network, the 2007 ATHENA Award recipient, the 2004 Wooster Chamber’s Small Business of the Year, member of Friends of Every Woman’s House, Have a Heart for Hospice, St. Mary’s Gabriel Project, Startzman Free Clinic’s Meal That Heals, Lincoln Highway Association, Akron University’s International Friendship Club, and past Volunteer of the Year for Quota International.

Rita’s sons are both in the cheese business, DJ is owner of Shisler’s Cheese House in Akron, Dennis is VP of Marketing and Webmaster for https://cheesehouse.com, at the Orrville Shisler’s. When not in the cheese store, or busy volunteering, Rita spends time being Oma to Daniel, Grace and Natalia Shisler.